- HOME

- BIOBAUERNHOF

- HOLZPRODUKTE

- Pfeffermühlen Salzmühlen aus Holz

- Pfeffermühlen Würfel

- Pfeffermühlen Natur (ohne Rinde)

- Pfeffermühlen mit Rinde

- Pfeffermühlen mit Lasergravur

- Pfeffermühlen mit Naturkante

- Pfeffermühlen Mooreiche

- Pfeffermühlen Einzelstücke

- Sets Pfefferstreuer und Salzstreuer

- Sets Pfeffermühle und Salzstreuer

- Sets Pfeffermühle und Salzmühle

- Sets Baumstämmchen Pfeffer- und Salzstreuer

- Doppelmühlen

- Pfeffermühlen mit Edelstahlmanschette

- Große Holzknobelspiele

- Schnapsservice

- Naturholzschalen

- Holzwanduhren

- Kräutertrockner

- Zirbenholzlüfter

- Windlicht

- Heuhocker und Heutisch

- Holzschemel

- Holzschilder mit Lasergravur

- Holz Schlüsselanhänger

- Holz Kleiderbügel

- Holz Schuhlöffel

- Holz Rührer

- Holz Schneidbretter

- Holzbesen und Bürsten

- Mama - Geschenke

- Papa - Geschenke

- Geschenkgutscheine

- Pfeffermühlen Salzmühlen aus Holz

- ALTHOLZSTÜCKE

- Altholz Standgarderobe

- Altholz Garderobenleisten

- Altholz Schuhgarderobe

- Altholz Sitzbank

- Altholz WC Ablageregal

- Altholz Weinglashalter

- Altholz Weinflaschenständer

- Altholz Weinflaschenhalter

- Altholz Toilettenpapierhalter

- Altholzbalken mit WC Bürstengarnitur

- Altholz Handtuchleiter

- Altholz Truhe

- Altholz Windlichtsäulen

- Altholz Bilderrahmen

- Altholz Bilderrahmen mit LED Beleuchtung

- HOLZLEUCHTEN

- Hängeleuchten

- Wandleuchten

- Deckenspots

- Balkenhängeleuchten

- Bretthängeleuchten

- Stehleuchten

- Altholzleuchten

- Altholz Hängeleuchte - Cube

- Altholz Hängeleuchte - Zerrissen

- Altholz Hängeleuchte - Alte Fichte

- Altholz Hängeleuchte - Alte Eiche

- Altholz Hängeleuchte - Balkenleuchte

- Altholz Wandleuchte - Cube

- Altholz Wandleuchte - Zerrissen

- Altholz Wandleuchte - Balkenleuchte

- Altholz Deckenspots

- Altholz Stehleuchte mit Natursteinsockel

- Altholz Stehlampe mit Edelstahlsockel

- Altholz Nachttischleuchte

- Baumstammleuchten

- Technische Daten / Holzarten / FAQ

- MASCHINENBAU

- WORKSHOPS

- Teamworkshops für Erwachsene

- Kreativ mit Holz für Kinder

- 11.04.26 Workshop Kräutertrockner

- 11.04.26 Workshop Wanduhren

- 09.05.26 Workshop Bilderrahmen

- 09.05.26 Workshop Stehleuchten

- 30.05.26 Workshop Pfeffermühlen

- 30.05.26 Workshop Liegestühle aus Holz

- 13.06.26 Workshop Pfeffermühlen

- 13.06.26 Workshop Kleidergarderobe

- 20.06.26 Workshop Pfeffermühlen

- 20.06.26 Workshop Schneidebrett

- 05.09.26 Anfertigung eines Zirbenholzlüfters

- 05.09.26 Workshop Stehleuchten

- FERIENHAUS BÄR

Cheese derinder machine EM-700

... debarks cheese wheels up to Ø700mm

Automatic, clean debarking of cheese wheels

Overall concept:

The EM-700 cheese de-rinding machine was developed for the quick and clean de-rinding of hard and semi-hard cheese wheels. It is suitable for cheese wheels from Ø160mm to Ø700mm. The machine has a horizontal turntable equipped with stainless steel mandrels.

The machine enables the cheese wheels to be de-rinded with even rind removal, resulting in less rind waste and maximising the cheese yield. Thanks to the smooth cut and flat surface, the cheese can be processed immediately after de-rinded. The machine is characterised by its simple operation and ergonomic working height and ensures fatigue-free working. The 2 wheels and the stainless steel handles on the side make the machine easy to manoeuvre.

Planer and scraper:

Different tools are available depending on the rind texture of the cheese. The scraper blades and slicer knives can be easily changed without tools.

Debarking:

The cheese wheel is placed on the mandrels of the turntable. The cheese is de-rinded from the outside inwards using the slicer arm.

The cheese is then turned over to remove the rind from the underside in the same way.

Product video:

Cleaning:

The all-round closed stainless steel machine housing can be completely rinsed and is inclined so that the water can drip off easily after cleaning. All components that come into contact with the product can be removed without tools and rinsed in the washing trough.

The machine is manufactured in accordance with European food standards and is intended for use in professional food processing.

Technical data:

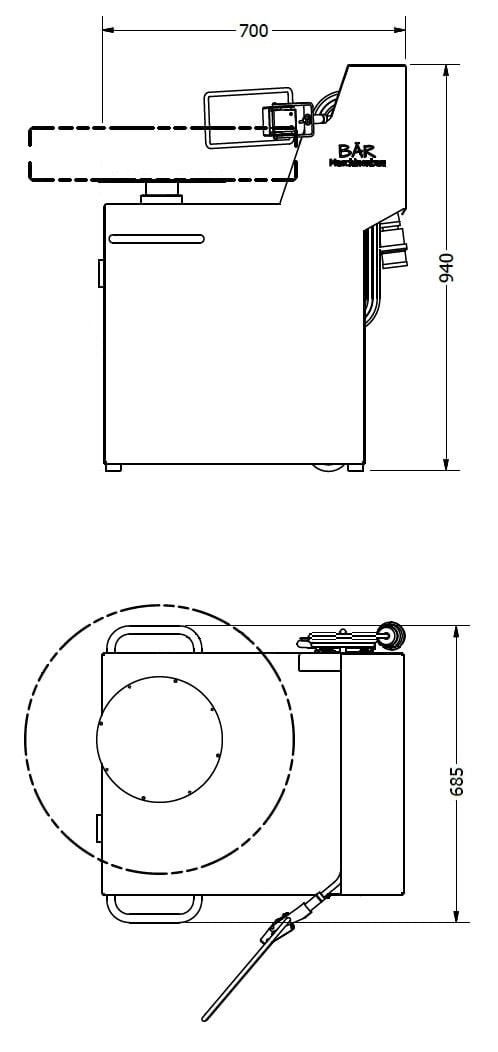

- for cheese diameters from 160mm to 700mm

- for cheese heights from 50mm to 160mm

- plug-in turntable with mandrels

- all-round enclosed stainless steel machine housing

- mobile base frame with 2 machine feet and 2 fixed castors

- electrical connection 380V, 50Hz, 16A CEE plug including 6 metre supply cable (optional 230V connection possible)

- produced in accordance with European hygiene and safety guidelines

Dimensions:

Equipment variants:

- Various disc diameters and mandrel arrangements possible

- Interchangeable slicer blade for fine-rind cheese

- Interchangeable scraper blade for coarse-rind cheese

- Adjustable speed

- Connection cable length as required

- Suction station (rind suction in container)

Output:

- 30 to 80 cheese wheels per hour, depending on the cheese diameter