- HOME

- BIOBAUERNHOF

- HOLZPRODUKTE

- Pfeffermühlen Salzmühlen aus Holz

- Pfeffermühlen Würfel

- Pfeffermühlen Natur (ohne Rinde)

- Pfeffermühlen mit Rinde

- Pfeffermühlen mit Lasergravur

- Pfeffermühlen mit Naturkante

- Pfeffermühlen Mooreiche

- Pfeffermühlen Einzelstücke

- Sets Pfefferstreuer und Salzstreuer

- Sets Pfeffermühle und Salzstreuer

- Sets Pfeffermühle und Salzmühle

- Sets Baumstämmchen Pfeffer- und Salzstreuer

- Doppelmühlen

- Pfeffermühlen mit Edelstahlmanschette

- Große Holzknobelspiele

- Schnapsservice

- Naturholzschalen

- Holzwanduhren

- Kräutertrockner

- Zirbenholzlüfter

- Windlicht

- Heuhocker und Heutisch

- Holzschemel

- Holzschilder mit Lasergravur

- Holz Schlüsselanhänger

- Holz Kleiderbügel

- Holz Schuhlöffel

- Holz Rührer

- Holz Schneidbretter

- Holzbesen und Bürsten

- Mama - Geschenke

- Papa - Geschenke

- Geschenkgutscheine

- Pfeffermühlen Salzmühlen aus Holz

- ALTHOLZSTÜCKE

- Altholz Standgarderobe

- Altholz Garderobenleisten

- Altholz Schuhgarderobe

- Altholz Sitzbank

- Altholz WC Ablageregal

- Altholz Weinglashalter

- Altholz Weinflaschenständer

- Altholz Weinflaschenhalter

- Altholz Toilettenpapierhalter

- Altholzbalken mit WC Bürstengarnitur

- Altholz Handtuchleiter

- Altholz Truhe

- Altholz Windlichtsäulen

- Altholz Bilderrahmen

- Altholz Bilderrahmen mit LED Beleuchtung

- HOLZLEUCHTEN

- Hängeleuchten

- Wandleuchten

- Deckenspots

- Balkenhängeleuchten

- Bretthängeleuchten

- Stehleuchten

- Altholzleuchten

- Altholz Hängeleuchte - Cube

- Altholz Hängeleuchte - Zerrissen

- Altholz Hängeleuchte - Alte Fichte

- Altholz Hängeleuchte - Alte Eiche

- Altholz Hängeleuchte - Balkenleuchte

- Altholz Wandleuchte - Cube

- Altholz Wandleuchte - Zerrissen

- Altholz Wandleuchte - Balkenleuchte

- Altholz Deckenspots

- Altholz Stehleuchte mit Natursteinsockel

- Altholz Stehlampe mit Edelstahlsockel

- Altholz Nachttischleuchte

- Baumstammleuchten

- Technische Daten / Holzarten / FAQ

- MASCHINENBAU

- WORKSHOPS

- Teamworkshops für Erwachsene

- Kreativ mit Holz für Kinder

- 11.04.26 Workshop Kräutertrockner

- 11.04.26 Workshop Wanduhren

- 09.05.26 Workshop Bilderrahmen

- 09.05.26 Workshop Stehleuchten

- 30.05.26 Workshop Pfeffermühlen

- 30.05.26 Workshop Liegestühle aus Holz

- 13.06.26 Workshop Pfeffermühlen

- 13.06.26 Workshop Kleidergarderobe

- 20.06.26 Workshop Pfeffermühlen

- 20.06.26 Workshop Schneidebrett

- 05.09.26 Anfertigung eines Zirbenholzlüfters

- 05.09.26 Workshop Stehleuchten

- FERIENHAUS BÄR

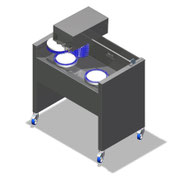

Cheese refining machine PM450

... for cheese wheels from Ø250mm to Ø450mm

Construction / Concept:

The PM-450 cheese care machine with 2 horizontal care stations brushes hard and semi-hard cheeses up to Ø450mm. The horizontal care stations are characterised by their excellent care quality. The operator always has an unobstructed view of the side of the cheese to be treated and therefore has constant control over the condition of the cheese surface.

The cheese care machine has two work stations which enable the operator to change the wheels quickly and efficiently. The operator places a cheese on one work station and can remove the finished cheese from the other work station and return it to the cheese rack. In the meantime, the newly placed cheese is brushed in the work station. This means that there are no empty times and the achievable care performance is very high.

Brushing and water supply are carried out independently by the machine. The machine care ensures that the wheels are brushed evenly and that a homogeneous cheese rind is formed.

The machine housing made of high-quality V4A stainless steel is hygienic and easy to clean.

The work station is easily accessible.

All components in contact with the cheese, such as brushes and support discs, are pluggable and can be easily removed and rinsed for simple cleaning.

The water pipes are hygienic and flushable throughout.

- Even salting and brushing of cheese wheels

- Even rind formation

- Ideal for hard and semi-hard cheeses

- Various brush hardness levels and shapes available

- Smooth operation, ergonomic working height

- Easy cleaning, hygienic design, maintenance-free design

- Always a direct view of the side to be cleaned and therefore optimum control over the ripening result

Product video:

Technical data:

- For cheese diameters from 250mm to 450mm

- For cheese heights from 60mm to 140mm

- Constantly adjustable contact pressure of the tanning side brush

- Constantly adjustable contact pressure of the surface brush

- Constantly adjustable lubricating water quantity

- Electrical connection 380V, 50Hz, 16A CEE plug with 6 metre supply cable

- Machine housing made of fully bath-pickled V4A stainless steel

- Flawless hygiene and food-compliant design in accordance with European hygiene and safety guidelines

- Option: adjustable brush speeds

- Option: 230V electrical connection

Dimensions:

Equipment:

- Surface brushes can be replaced without tools

- Tanning side brushes can be replaced without tools

- Support plates can be replaced without tools

- 30 litre stainless steel salt water tank

- Sealless, hermetically coupled lubricating water pump

- Mobile housing with 4 stainless steel swivel castors

- Option: with two support brackets for placing a cheese board on the machine

Performance:

- cares for 250 to 500 cheeses per hour